Lumber Material | Buckhannon, WV

Weyerhaeuser

Weyerhaeuser called Moffitt to reduce air temperature at the floor and upper levels of the facility during the summer, when the heat would get the highest. This lumber building material facility got incredibly hot during the summer, up to 117 in some places, so a new ventilation solution was vital. Additionally, they were trying to remove the haze of fog and smoke that gathered at the plant's ceiling.

Using temperature data taken by Moffitt, as well as the findings of a previous third-party air study, Moffitt figured out where the air was trying to go and how to provide the best ventilation solution. Moffitt designed a CFD model that showed that the new system could achieve a temperature reduction of 17°F at the 5-foot elevation.

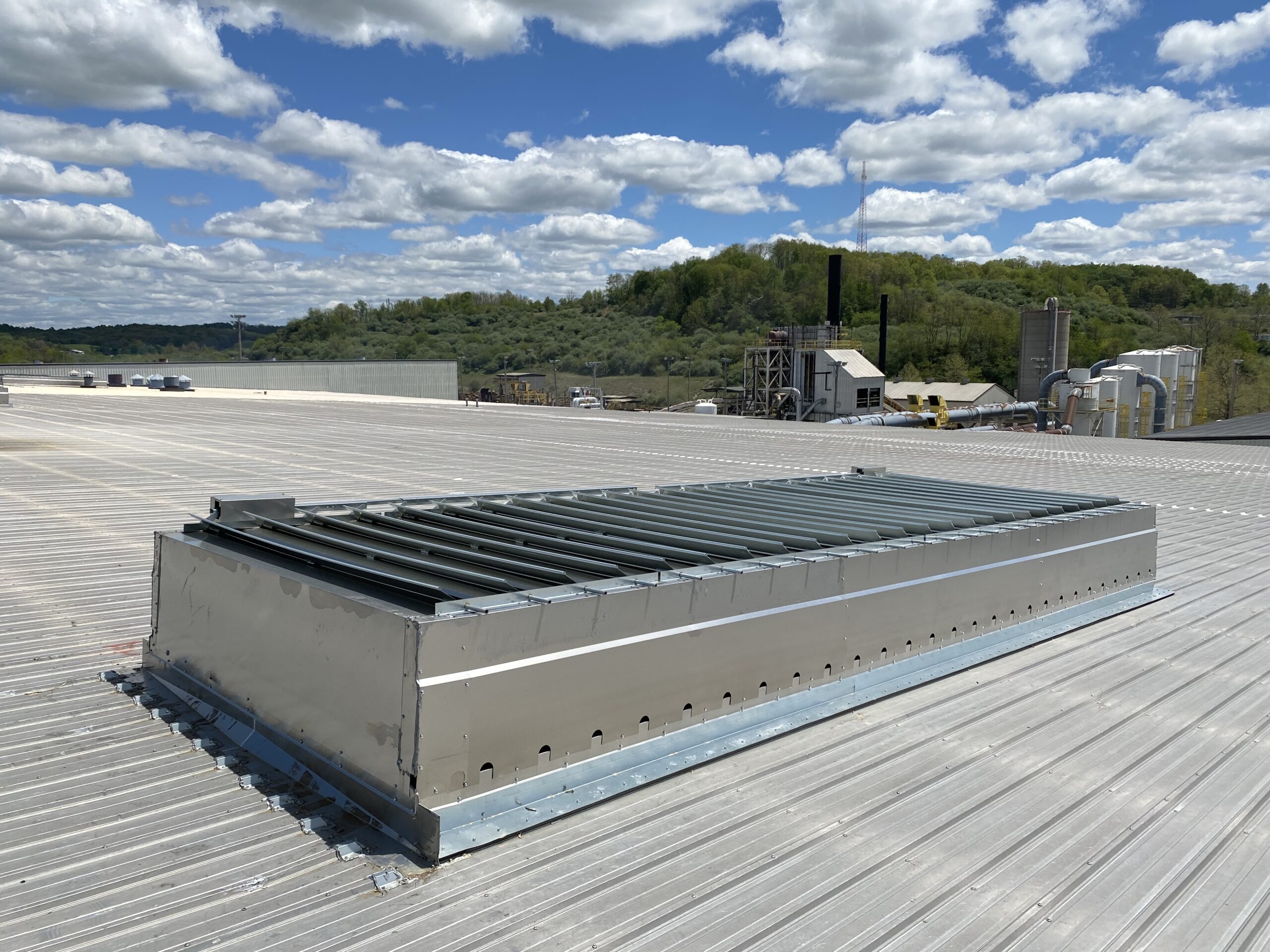

Moffitt supplied, manufactured, and installed ten (10) MatrixVent low-profile ventilators. Three temperature sensors were also added to allow for the dampers to close automatically when needed. Six vents sit above the main building and another four sit above the dryer area.

RESULTS

The MatrixVent ventilators decreased temperatures in the plant immediately. Furthermore, the new vents eliminated the haze that had previously hung over the entire plant. Now the facility is cooler and clearer throughout.

Project Summary

- Ten (10) MatrixVent low-profile ventilators

- Three (3) temperature sensors

- Equipment Installation