Glass Plant | Spring Hill, KS

Cardinal Glass

Cardinal Glass in Spring Hill, Kansas was experiencing some very unpleasant summers. Excessive heat was getting trapped within the lehr hall at the glass plant. This in turn was hindering the production process and creating unbearable work conditions. Additionally, the plant was experiencing low temperatures in the winter.

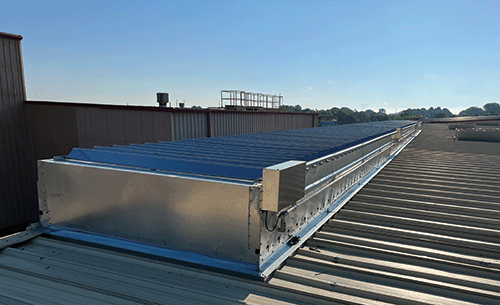

Moffitt developed a new solution utilizing fans, louvers, and a roof vent. The exhaust fans evacuate heat and maintain a consistent temperature between the north and south sides of the lehr. The supply fans and wall louvers bring cool fresh air in, while also improving air movement. Finally, a MatrixVent exhausts the hot air from the process area.

Automatic sensors, or manual controls, open and close the vent damper and wall louvers as required. Additionally, they turn the fans on and off as needed. This helps maintain a more comfortable, and more uniform, temperature in the lehr, all year long. Moffitt has the solution for glass plant ventilation.

Project Summary

- One Hundred Forty-One (141) ES90 natural wall louvers

- One (1) MatrixVent low-profile ventilator, 10’ x 145’

- Three (3) Direct Drive Fan Supply, 42”

- Four (4) Direct Drive Fan Exhaust, 42”

- Installation