Guide to Roof Vents for Industrial Ventilation: Why They Matter

The Essential Guide to Roof Vents for Industrial Ventilation: Why They Matter

A roof vent is an essential part of industrial ventilation systems, providing an avenue for hot air to escape. They improve air quality on residential, commercial, and industrial buildings. As temperatures increase, proper ventilation in industrial settings is vital for the well-being of workers, the longevity of the equipment, and overall productivity within the workplace. This guide explores the different types of industrial roof vents and the role they play in improving industrial environments.

The Science Behind the Roof Vent

The roof vent is a simple device that harnesses the natural physics of air induction. As the temperature inside a building rises, the warm air rises and becomes trapped under the roof. Direct sun and higher outside temperatures can drastically increase the internal temperature as well. This can lead to deadly conditions and premature equipment failure.

Installing roof vents provides escape routes for this hot air while protecting the building from weather and pests. When paired with floor-level intakes, cooler air pushes the hot stagnant air out allowing temperatures inside to drop as much as 30℉.

The Importance of Roof Vents for Industrial Buildings

In industrial settings, work areas can reach extreme temperatures, especially in industries that utilize heat processes during production, such as forges, glass manufacturing, and food processing. This can cause far-reaching consequences if not properly addressed.

Improve Worker Safety

Working in a hot and stuffy environment is unpleasant and with today’s innovations in ventilation systems, an unnecessary risk. Workers have many employment options and will seek cooler working conditions even if they love the job and management. The human body can only be exposed to elevated temperatures for so long before vital systems shut down, leading to heat sickness and increased workplace injuries, not to mention drastically reduced productivity, efficiency, and accuracy. In fact, California recently passed the Indoor Heat Illness Prevention Regulation. This rule mandates that industrial facilities have adequate ventilation and maintain safe working temperatures. We explore more in our post, New Heat Rules for Indoor Workers.

Protect Equipment Lifespans

Poor ventilation also takes its toll on industrial equipment. Moisture and particulate matter thrive in hot areas. They can lead to corrosion as they accumulate on surfaces and within mechanical equipment. Over time, this accumulation breaks down seals and degrades metals, leading to increased maintenance and premature equipment failure. Consequently, industrial roof vents can drastically reduce moisture and debris accumulation by allowing the hot air to escape, taking the contaminants out with it.

Enhance Productivity

When workers are comfortable and equipment is running optimally, productivity is improved. However, when workers overheat, they naturally slow down. Prolonged heat stress may cause trouble thinking or disrupt vision which can unintentionally reduce work quality and accuracy. By improving industrial ventilation, workers are more comfortable and are less likely to cause production delays.

Types of Industrial Roof Vents

There are many types of roof vents available to help improve ventilation and most can be combined with other processes for increased air turnover.

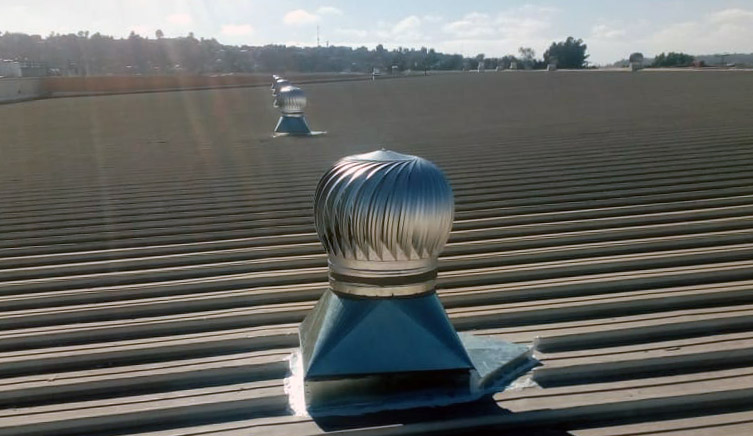

Turbine Vents

A type of passive natural ventilation, turbine vents are best used on smaller facilities. They use the power of the wind to pull the hot air out of the building. Even the slightest breeze will engage the vent, causing the turbine to spin. This vacuum-like effect pulls the hot air up and out reducing the internal temperature.

Low-Profile Vents

These vents work great on larger buildings where more exhaust is required. They also provide a more streamlined appearance for buildings where architectural style is important. Often used in high-heat and high-humidity applications, such as those common in the metal or paper industry, these vents provide greater overall air exchange. A low-profile vent can reduce temperatures by as much as 30℉. Low-profile vents minimize wind load and divert rainfall, making them well-suited to diverse climates.

Continuous Ridge Vents

In industrial applications where internal temperatures can reach extremes, larger continuous ridge vents allow greater air turnover, drawing the hot air up and out, cooling facilities by up to 30℉. When used with powered exhaust systems, these vents can reduce internal temperatures below the external ambient. Small ridge vents, like the Model RR, can provide similar relief in smaller buildings.

Open-Air Vents

In buildings where continuous, uninterrupted airflow is needed, such as metal forges and warehouses, open-air vents are the best choice. These roof vents allow 100% efficiency by opening the roof vent completely. Additionally, state-of-the-art rain sensors tell the flaps to close when weather conditions change. This prevents rain from entering the building.

Custom Roof Vent Solutions by Moffitt

Choosing the ventilation system that is best for your particular application will depend on a number of factors, such as:

- Building Size

- Roof Pitch

- Industrial Applications

- Environmental Factors

At Moffitt, we have been improving working conditions in industrial settings with custom ventilation solutions for over 60 years. We have dedicated engineers located throughout North America ready to make site visits and provide free evaluations and ventilation designs. They are here to help cool your industrial buildings for optimum worker comfort.

Contact us today to learn how we can help you improve your industrial ventilation system and protect your investments.