Maximizing Industrial Efficiency: The Role of a Ventilation Exhaust Fan in Industrial Facilities

As a leader in custom industrial ventilation systems, we know how a ventilation exhaust fan can improve overall efficiency within industrial settings. Too many buildings simply have the wrong ventilation: underpowered, overpowered, or fans instead of vents. Buildings with the right ventilation experience a drastic upward shift in productivity, operational efficiency, and cost savings. Installing the right exhaust and supply fans maximize industrial efficiency in several important ways.

Efficiency Booster #1: Temperature Regulation

No one likes working in a sweltering, stuffy environment—the human body can only take so much before it starts to slow down. The electronic components in modern manufacturing facilities are also prone to failure in extreme temperatures. Improving air exchange, either through exhausting the stale hot air or introducing fresh cooler air—ideally both—helps maintain more comfortable and productive working conditions by keeping temperatures at safer levels.

Efficiency Booster #2: Moisture and Humidity Management

Hot, humid air holds moisture, encouraging condensation accumulation that can lead to equipment damage, building maintenance issues, and worker illnesses. All of which can drastically affect overall efficiency. Moisture-producing processes, like a former in a paper mill, only add to the risks of water damage, mold and mildew growth, and illnesses. Industrial ventilation exhaust fans boost air turnover rates, expelling the humidity out of the building and preventing this accumulation.

Efficiency Booster #3: Energy Efficiency

Maintaining safe indoor temperatures in already hot industrial facilities puts a lot of stress on industrial ventilation systems. This high temperature stress causes ventilation systems to consume a great deal of power to meet the increased demands. With proper ventilation, industrial ventilation systems don’t have to work as hard, reducing their energy consumption and overall operating costs. In some cases, industrial ventilation systems can be designed to include natural ventilation solutions, reducing power consumption and costs even further.

Efficiency Booster #4: Regulatory Compliance

With the average high temperatures breaking records on an annual basis, federal and state indoor heat regulations are becoming more and more common, putting older facilities at risk of hefty fines (up to $25,000 for a serious offense in California, and even work stoppages due to non-compliance. Upgrading ventilation systems with an industrial exhaust fan will help improve working conditions and bring operations into compliance, preventing costly downtime and worker injuries. In some instances, this is as simple as fixing some old fans, in others it may include a whole new ventilation system. Better to find out before the fines come in.

Efficiency Booster #5: Odor and Fume Removal

From the exhaust fumes from trucks at a loading dock to the steam released during a high-temperature process, the air in industrial facilities can be full of harmful contaminants. These contaminants can cause productivity drops, equipment malfunctions, and worker illnesses. Stale, hot air filled with dust and other contaminants can play havoc on overall efficiency. Not only can poor air quality cause worker illnesses that might result in slower production or missed shifts, but it can also reduce the accuracy and life span of sensitive equipment. When used in conjunction with adequate filtration, industrial ventilation fans are essential for removing harmful airborne contaminants caused by manufacturing processes, promoting a healthier environment for optimal performance and productivity.

How the 3 Main Types of Exhaust Fan Boost Efficiency

Industrial ventilation demands greater air turnover than conventional systems due to the size of the facilities and common heat-producing processes. Depending on a number of factors, industrial buildings may require powered or hybrid ventilation solutions that include one or more of our specially designed exhaust fans that further improve industrial efficiency.

Wall-Mounted Exhaust Fan

These high-efficiency fans are ideal for facilities with limited roof access or those needing targeted ventilation, such as buildings with heat-producing processes. Their space-saving design doesn’t interfere with equipment or workflow, promoting quicker heat dissipation in crowded environments. This helps maintain cooler working conditions to improve productivity while lowering power consumption and the corresponding costs.

The Model P Series Wall Fans at Moffitt are designed to provide powerful airflow in either exhaust or supply configurations.

Upblast Exhaust Fan

As their name suggests, an industrial exhaust fan forces hot air out of, and away from, the building. These are our most popular fan, and they are ideal for almost any industrial and commercial processes that generate heat. This includes everything from commercial kitchens, to foundries, to certain manufacturing facilities. The upblast design pulls hot air, fumes, grease, and other airborne contaminants out of the facility and away from the building. Ultimately preventing the pollutants from accumulating at the ceiling. This prevents long-term maintenance issues.

Our Model V Series Upblast Roof Fans were specifically developed to efficiently provide high-volume air movement for industrial applications. These fans are incredibly popular with our customers.

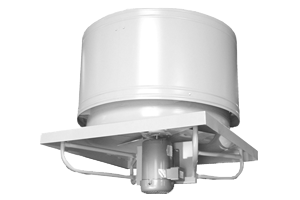

Hooded Roof Ventilation Exhaust Fan

Similar to upblast fans, hooded roof fans expel overheated air, moisture, and fumes from industrial facilities. The hood ensures continuous airflow even in intense wet, windy conditions. This protects the equipment and facility from moisture damage while the improved airflow removes contaminants. This improves air quality and ensures an optimal working environment and regulatory compliance in areas prone to rain and snow.

Moffitt Model H Series Hooded Roof Fans can be used as either a ventilation exhaust fan or as a fresh air supply fans and are ideal solutions for improving airflow in any industrial environment.

Let the Experts at Moffitt Boost Your Industrial Efficiency with Custom Ventilation Solutions

Determining which type of exhaust fan is best for your operations can be complicated. Finding the right ventilation exhaust fan depends on building geometry, roof height, heat-producing processes, and more. Between the rising average temperatures and the increasing indoor heat regulations, upgrading industrial ventilation systems is more important than ever before. At Moffitt, we are committed to helping you improve working conditions through better ventilation and temperature regulation.

Contact us today to schedule your free on-site consultation and ventilation system design, and let the experts boost your industrial efficiency with custom ventilation solutions.