How Does a Pressure Gravity System® Work?

A Pressure Gravity System®, also known as natural draft systems, is one of the oldest ways to obtain fresh airflow in an enclosed space. Each Pressure Gravity System® uses positive pressure to help ventilate manufacturing and industrial properties. Temperature differentials between the air inlets at the floor level and the ventilator at the roof level contribute to the movement of air. By exploiting the natural convection effect, air can be exhaust through the roof of a building naturally.

Powered exhaust fans assist this process by forcing cool, clean air into the building at a high velocity. Powered fan systems promote air flow and reduce temperature differentials inside and outside of a building. Not only is this form of cooling environmentally friendly, but it also saves significant amounts in energy costs.

How Does It Work?

The pressure gravity concept is often used in spaces such as large manufacturing and industrial spaces. To create a Pressure Gravity System® the first step is to create a roof opening. A natural ventilator designed to let air naturally exhaust from the building covers the opening.

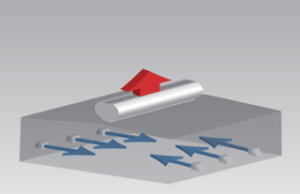

Concurrently, a team will install intake wall fans near ground level to provide supply air. These powered supply fans pressurize the building. They direct cool air to directly into the troubled “hot spots”. This ensures that areas that don’t need cooling, aren’t cooled. Fans point inward, with the discharge end facing into the building, to cool the work floor deep in the building.

Pressure Gravity System® in Action.

This combination of the passive exhaust with active intake results in superior air movement and an increased cooling effect inside of the building.

A byproduct of this system means that the supply fans are moving cool, clean air, as opposed to hot, dirty air, removing the fans’ exposure to the hot, humid conditions that over-tax exhaust fans and can lead to rusting. This means they need less maintenance and fewer repairs. Of course, the fans are easier to access and maintain because they are at ground level. Unlike roof mounted fans that are hard to get to, wall mounted fans are easy to reach.

Fortunately, designing for a Pressure Gravity System® is easy as well. In addition to temperature data and building dimensions, they also consider intake air. A ventilation designer can find the ideal intake fan by looking at the building CFM. Matching this with fans of corresponding size and horsepower ensures the best system possible for that space.

What is the Difference Between a Pressure Gravity System® and a Natural Ventilation System?

A Pressure Gravity System® requires less square footage for gravity ventilators than a natural ventilation system. Additionally, the powered supply fans create a higher-pressure differential than that created by natural ventilation. In turn, this increases the air velocity through the ventilator.

Gravity ventilation is an energy efficient way to naturally cool buildings. It uses less energy on average than a powered exhaust system. Each system fits your specific building’s needs. This system can grow and change over time. Meeting cooling requirements as your business or facility changes.

In conclusion, Moffitt Corporation offers an array of ventilation products including those for natural ventilation, axial fans, specialty fans, centrifugal plans, and heaters. Moffitt Corporation, the only place you can get a Pressure Gravity System®, prides itself on being a leading ventilation designer and installer since 1961 with satisfied customers all over the world.