Science

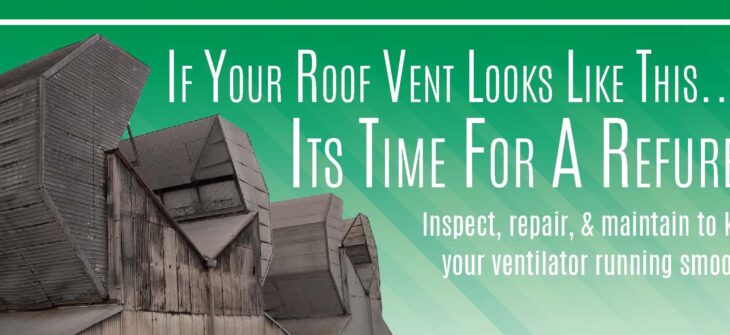

The natural ventilator is the workhorse of the industrial ventilation system. They often last for 50 – 100 years and simply sit on the roof and do their job. They don’t require much attention and often ignored until there is a problem. Maintenance is seldom required, and little energy is used. It is common to

Natural ventilation discovery, and the early days of Moffitt, in our Caveman Creativity video. This tongue-in-cheek-cartoon shows how the Caveman found out about natural ventilation. Watch this short video below to see the ingenuity of the Caveman in action. Natural Ventilation Discovery thanks to the Moffitt Caveman Through trial-and-error, he created the MoffittVent. Natural Ventilation

Industrial ventilation savings can have a huge impact on your bottom line. Paying for low-efficiency fans, or buying a HVLS that just moves hot air around, can make your energy and maintenance costs soar. Fortunately, Moffitt is here to help. See what kind of savings you can achieve with our ventilation solutions. Choosing the Right

One of the major trends of the 21st century is green construction and green energy. Retrofit an old building with a new ventilation system to increase energy efficiency. With more than half a century of experience in the green energy industry, Moffitt Corporation is an expert in green ventilation systems. As a result, we are

Consider a natural ventilation system for your new building ventilation. It is all too common to just choose the most common solution (air conditioning, ceiling fans, etc.) for a building, but finding the right ventilation solution for your specific facility can make all the difference. Of course, you need to evaluate the options by asking

All too often new customers push back on a new solution because they say that ventilation doesn’t make them money. It’s easy to see the return on investment for a new machine, but it’s harder to see how improving airflow will help. However, we’ve seen time and again how a new ventilation solution can save

All types of manufacturing processes use compressed air. In fact, every process and machine found in an industrial environment use some form of pressurized air or gas. Unfortunately, because it is so commonplace, people fail to recognize it as the potential hazard that it is. As little as 12 PSI can be deadly in the