6 Common Industrial Fan Safety Hazards

As safety is always our priority, we thought we’d take a minute to focus on some industrial fan safety hazards. A fan has a lot of moving parts and as a result, this leads to a lot of safety issues for those who will need to work with them. Ensuring that your industrial fan is up to date and in good working order lowers the chances of it causing injury to those who need to be around them.

At Moffitt, we sell everything from small axial fans to large, hooded supply fans. Despite differences in sizes, motors, and configurations, each and every one shares the same industrial fan safety hazards. Below is a list of some of the common hazards to look out for.

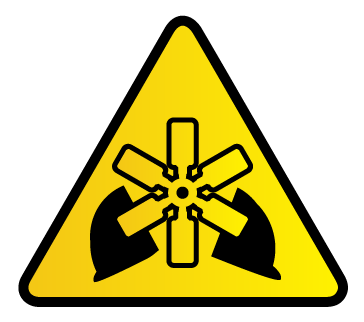

1) Contact with Rotating Blades

Contact with the rotating propeller is probably the most obvious hazard around an industrial fan. That is why everytime a fan is on, it must be treated with vigilance and care. Even the smallest touch can lead to loss of limb or life.

Lockout and tag out the unit when working on industrial fan equipment. Test it by operating the starter to ensure the unit is de-energized. Do this before removing any guards.

2) Debris Entering The Fan

It’s not just fingers and appendages that you need to keep out of the path of the fan, but other material as well. Spinning fans are immensely powerful. Everything from hand tools to your cell phone will get chopped to pieces by a fan. Even A full brim phenolic hard can be reduced to fibers if it gets in the way of the fan.

Furthermore, this will assuradely damage the fan and get debris everywhere. Remove dunnage, shipping material, and equipment before start-up. This indirect contact can also lead to dangerous flying particulate which is particularly hazardous to eyes and respiratory system.

3) Pinch Points in Belts / Sheaves

Even if the fan wheel is rotating slowly, without power, a significant mechanical advantage is developed at the sheaves. This is especially true with large fans. A finger caught between the sheave and the rotating belt could result in severe injury or digit loss.

Also remember that even a slight wind can cause a still propeller to rotate without any power. For that reason, always be sure to secure the propeller before performing mainteance.

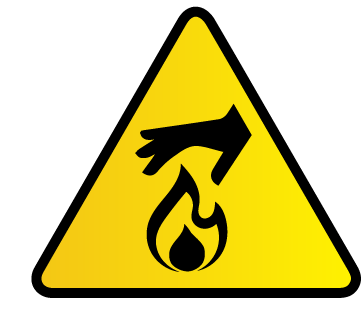

4) Contact with Hot Motor Surface

The fast rotation of fans generates lots of heat. As a resul, they will retain that heat for an extended period of time after they are deactivated. External unit temperatures can reach 220°F or higher. It is vital to let the unit cool down completely before starting work. Make sure to give the unit plenty of time to cool and wear the appropriate protective gear.

5) Fan Guards and Mounting

Fan guards keep foreign objects from entering the fan and keep objects from falling into the building below. However, a broken guard, or even the guard itself, can become an industrial fan safety hazard.

Guards should be in good operating shape and properly secured to the fan housing. Use the correct number of sheet metal screws. If unsecured, guards can fall into the fan or onto workers.

During mainteance, be careful when removing guards. They tend to be large and flexible. This can result in loss of balance when working on elevated surfaces and ladders. Finally, guards often contain sharp edges from expanded metal and other screen materials. Wear gloves when handling all screens.

6) Blow Back

A large fan propeller will have significant mass and can produce a lot of force. As a result, a burst of air can knock you off your feet. Depending on your location on the roof, this can be fatal.

In addition to power deactivation, normal tie-off procedures should be practiced during rooftop fan maintenance.

Avoding Problems During Initial Start Up

Fans travel long distances to get to your facility. They encounter vibration, bumps, and weather along the way. That is why you inspection, and start-up is so important. Be sure to.

- Look for loose/missing components and damage

- Correct all discrepancies before starting the fan.

- Listen for any unusual noises, squeaks, squeals, hum, or rubbing.

- Make sure the blade does not contact any part of the spinning area or drum.

These issues should be cause for immediate unit rejection. Correct these problems immediately as running in this condition will result in very quick blade failure.

“Bump” each fan before committing to a full power run. “Bump” means applying a short burst of power to start the fan wheel rotating, then immediately de-energizing the unit. This will help you see if there is blade wobble or tracking problems with the fan.

6 Common Industrial Fan Safety Hazards

In conclusion, knowing the rules of fan guards is an important first step to ensuring workplace safety. A site inspection is a great first step to ensuring that your fans are safe and in proper working order