The Importance of Natural Ventilator Inspections

The natural ventilator is the workhorse of the industrial ventilation system. They often last for 50 – 100 years and simply sit on the roof and do their job. They don’t require much attention and often ignored until there is a problem. Maintenance is seldom required, and little energy is used. It is common to completely forget about a ventilator until there is a problem. While is easy to see when a piece has broken off or when the sheeting has rusted through, it’s important to discover these issues early. Moffitt Corporation encourages proactive natural ventilator inspections as routine inspections can find any problems or issues before they become dangerous.

Save Your Building, Get a Ventilator Inspection

Making sure your industrial ventilator, like a Clamshell or MoffittVent, is in proper working order is important for the health and safety of your team. Furthermore, a properly maintained vent will keep you from spending more money in the long run. Scheduled ventilator inspections are especially important. They don’t need to be done every month, or even every year, but they should be on the maintenance schedule. During routine ventilator inspections, we see many glass plants have insufficient or deteriorating systems that need attention right away. These problems are inevitable but fortunately, the design of the vent means repairs are relatively easy.

Water Leaks

Water leaks are the most obvious ventilator vent issue. As a ridge vent is a weather protected hole in the roof, the worst thing that could happen is for rainwater or snow to enter. Rust and other sheeting damage are most often responsible for this problem. As holes or creases widen increasingly can get through.

This is where being proactive can help. Finding small holes before they become big holes is important. Small water leaks can become big water leaks and destroy any ventilation system over time. Finally, regular maintenance and scheduling ventilator inspection times prior to severe weather can help prevent major damages or issues.

Prevent Corrosion

Corrosion is a major problem for any metal components in a high-heat, high-humidity environment. It is even more of a concern in areas where cold weather puts stress on the component parts very quickly. The build-up of caustic batch dust and/or production flameouts can make this problem even worse.

Of course, this problem has a relatively simple solution. Prevent larger corrosion problems by cleaning out batch dust and isolating rusted sections will help. Also, choose a new ventilator that can handle the correct volume of heat and humidity in your building. Corrosion is the biggest problem for natural ventilators. Being proactive is the key.

Broken Components

By checking up on your vents you can find pieces that are wearing out instead of pieces that have already broken. Angles, gears, and other components all have their own specific life cycles, and it is important to keep up with them.

All too often a single broken component is just the first of many. Broken pieces act like dominos with one broken part often leading to the break of another. For instance, a single worn-out gear will cause the other gears to turn improperly and subsequently wear out themselves. Proactive inspections and preventative maintenance are the best way to avoid this.

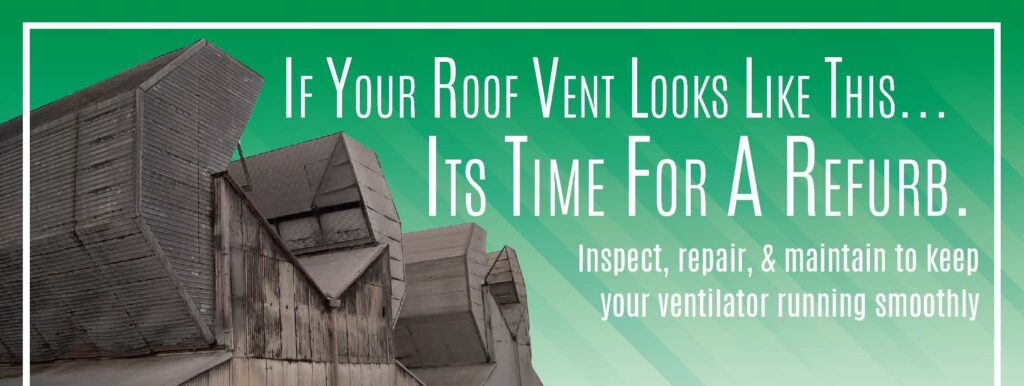

Refurbishing Your System

Refurbishing a system, or retrofitting a brand-new ventilation system, can be the key to your industrial ventilator woes. If you notice any issues that could require repairs, or if you think it’s just been a while since you inspected your system, it might be time to call Moffitt. As the experts in natural ventilation, we’ll be able to review your entire system and help identify any problem areas. We know what to look for and the best way to fix it. Of course, we also know how to move around and inspect a roof vent safely and quickly, avoiding the dangers of rooftop accidents.

Many companies find it helpful to set up yearly ventilator inspections to ensure that they always stay on top of their vents’ conditions. That way they can compare system from one year to the next and be able to spot what is a problem and what is a non-issue. See how long the system has before components require repairs.

Ventilator Inspections

In addition to working properly, it’s also important to make sure your vent is working efficiently. A natural ventilator inspection is the best way to do that. Technological advancements and engineering improvements make today’s natural ventilators more efficient and effective than ever before. Increased durability, stronger weather-tightness, and lighter weight units make for longer-lasting natural ventilation. Refurbishing an old, outdated ventilator can make a world of difference in any glass plant.

The other half of the equation is making sure you have the right ventilation system for your facility. Ventilation problems are common when production capacity is expanded without updating the ventilation system. The old system’s set-up is now inadequate when the brand-new production line is added. As each natural ventilator moves a certain volume of air, it is important to make sure the new system matches the new ventilation requirements. Proper ventilation capacity is the key to ensuring a well ventilated and comfortable work floor.

Whether or you have a clamshell vent, a ridge vent or any other industrial ventilation system, Moffitt Corporation can help you. Our natural ventilator specialists will be able to see more than the most obvious problems and let you know how to fix them. Call Moffitt for your ridge vent inspection today.