Start Planning for Hotter Temperatures Now: What to Know About Industrial Venting Systems

With much of the USA still under winter’s thumb, it’s hard to imagine the sweltering temperatures that will be upon us before we know it, and with them, the risks of indoor heat-related injury and OSHA violations. However, those hotter days are inevitable, and taking steps in the cooler months will help provide a more comfortable, safe, and productive environment during the dog days of summer. Understanding the different types of industrial venting systems is the first step in making informed decisions regarding upgrading your ventilation for improved working conditions and ensuring regulation compliance.

Understanding the Basics of Industrial Venting Systems

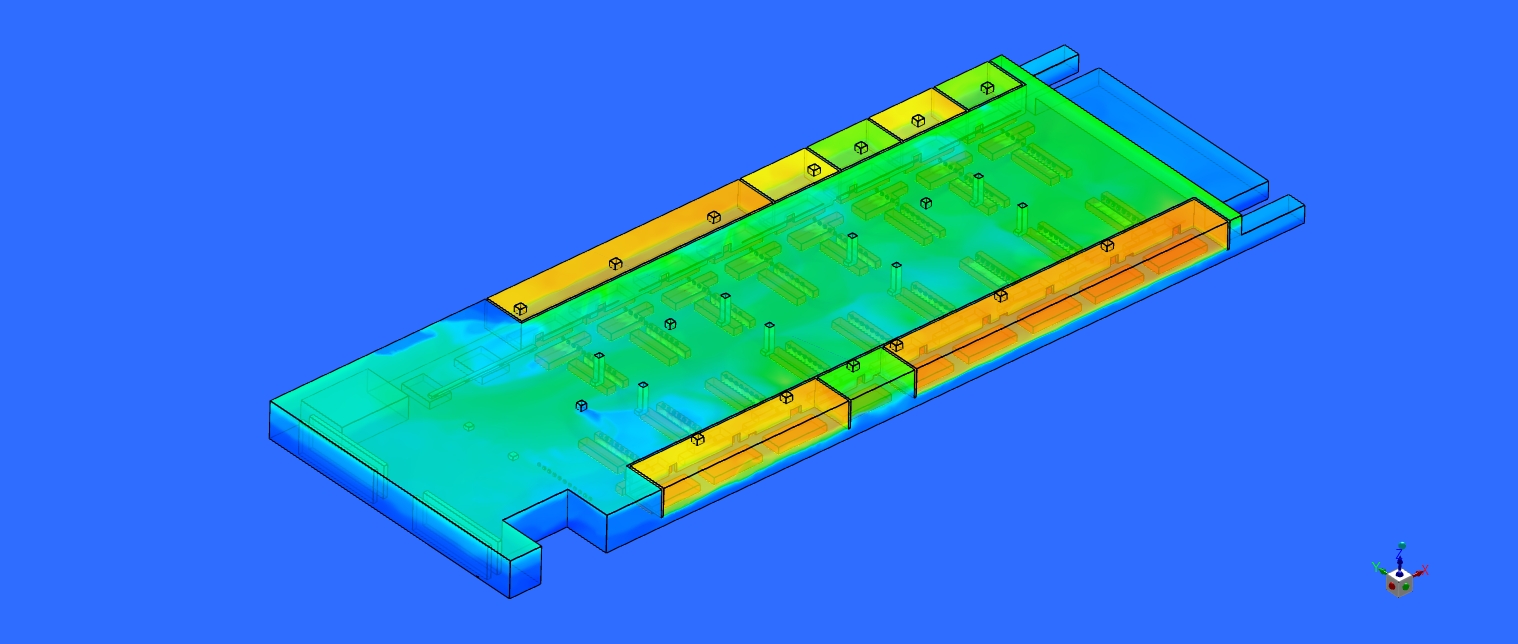

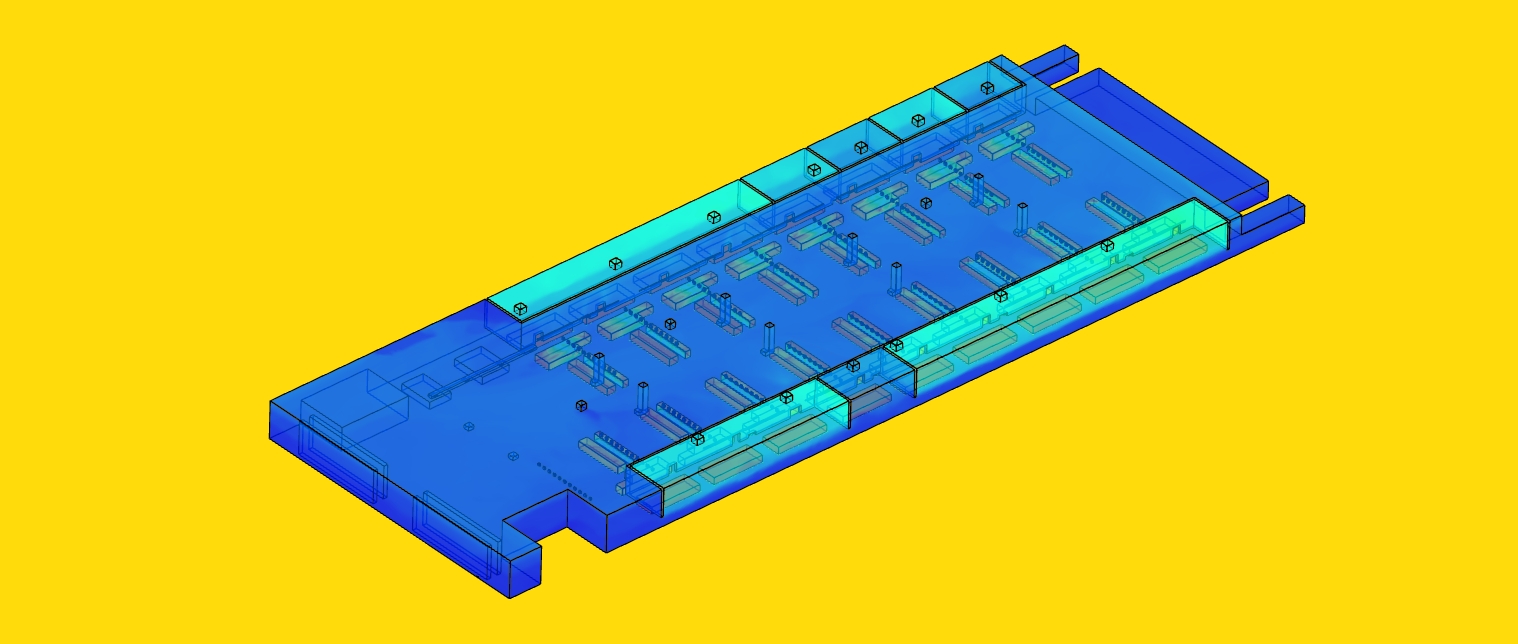

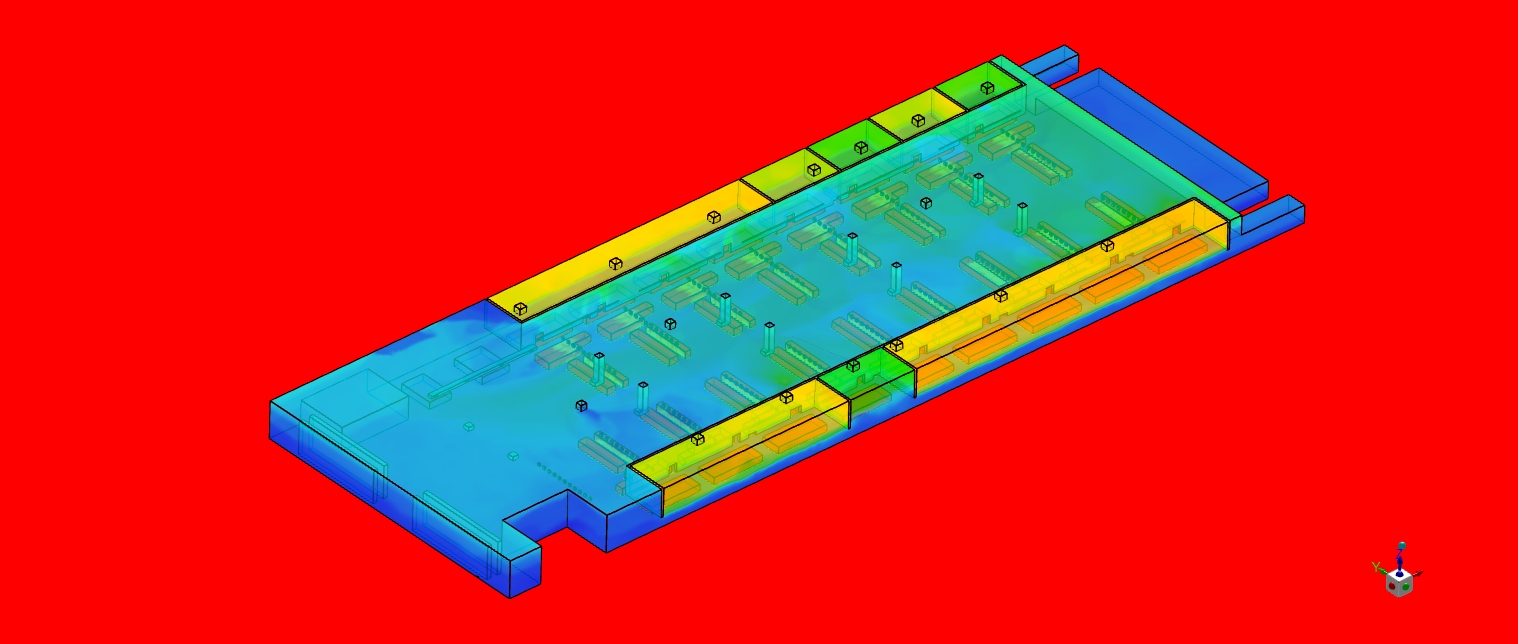

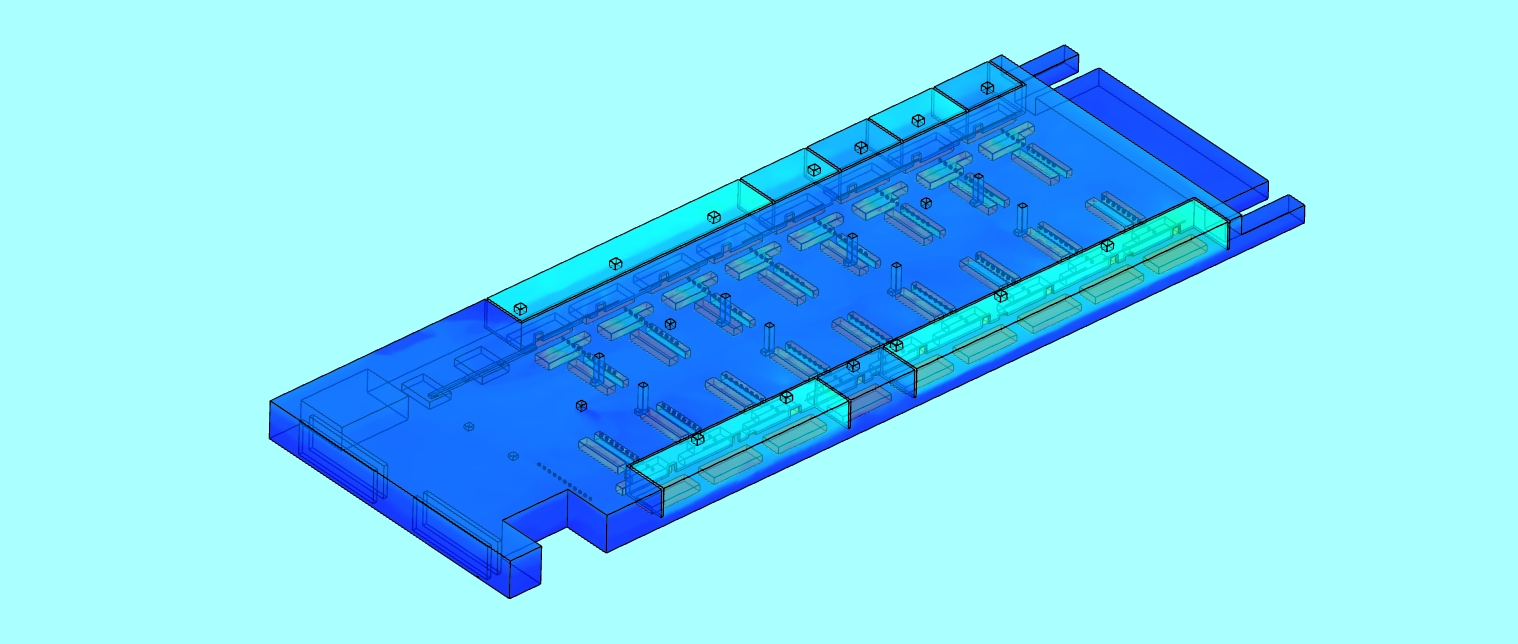

Industrial venting systems are essential to maintaining adequate airflow and cooler internal temperatures throughout the building. These systems work by pulling fresh air through wall louvers and pushing hot, stale air out through roof vents. As hot air escapes at the roof level, cooler air rushes in to replace it, effectively cooling the area by up to 30°F and creating more comfortable working conditions. These systems are designed to provide optimal airflow through the space. However, each system must be custom-engineered due to the complexity of an individual building’s unique construction, configuration, heat-producing processes, and environment.

Industrial venting systems keep the interior the right temperature whatever the weather outside. Click the arrows to see how the conditions change throughout the year.

Types of Industrial Venting Systems

Industrial ventilation systems combine wall louvers, roof vents, fans, evaporative cooling systems, make-up air units, and other specialized equipment to improve working conditions. Ventilation systems can be divided into three main types, each characterized by their power requirements.

Natural Ventilation Systems

Natural ventilation systems use thermodynamics, not electricity, to efficiently cool buildings. Hot air naturally rises and becomes trapped under the roofs of buildings, causing the internal temperature to climb. However, industrial roof vents, such as the MoffittVent, allow this hot, stagnant air to escape, preventing that rise in temperature. As the hot air leaves the building, wall louvers – and air displacement- pull cooler air in at the ground level. Most industrial and commercial buildings can benefit from improving their natural ventilation. This type of venting can improve working conditions by lowering internal temperatures by up to 30°F. All without relying on additional power consumption. Making it a more cost-effective way to control temperatures in your facility.

Powered Ventilation Systems

In buildings with low roofs, crowded work areas, or high-heat processes, powered ventilation systems are likely the best option. These systems still take advantage of thermodynamics, pulling in cooler air and forcing out the hot, but they utilize mechanical processes to boost airflow and improve air turnover. Strategically placed industrial fans, for example, can push hot air away from workers. Or, alternatively, they can be turned around to provide a pleasant breeze. This breeze can mean the difference between loyal employees and a costly retention rate in extreme heat-producing areas. Better ventilation helps reduce worker turnover in facilities such as glass plants, steel mills, or even corrugated box plants.

Hybrid

Hybrid industrial venting systems utilize both technologies to provide optimal air exchange, cooler interiors, and a more comfortable working environment. A warehouse, for example, may utilize MoffittVent ventilators for hot air exhaust, and side wall fans for fresh air intake. With the wide range of industrial venting options and the complex nature of thermodynamics, determining the best blend of natural and powered ventilation requires extensive experience. That experience, plus a thorough site evaluation by ventilation experts, is only available from Moffitt.

Start Planning for Hotter Temperatures Now

In conclusion, custom industrial venting systems by Moffitt are in high demand due to their efficiency and cost-effectiveness. A new system from Moffitt can reduce internal temperatures by up to 30°F. Now is the time to start planning for higher temperatures by requesting a free evaluation of your industrial venting system. Contact us today to learn more..

Recent Posts

- Reducing the Impact of Tariffs on Industrial Ventilation

- Conquering Corrugated Heat Under the Arizona Sun with Custom Plant Ventilation Solutions

- Elevate the Game in 2025 – A Note from John Moffitt.

- 6 Signs That It’s Time to Upgrade Your Industrial Ventilation

- Start Planning for Hotter Temperatures Now: What to Know About Industrial Venting Systems

Categories

- CFD Modeling (17)

- Commercial Ventilation (28)

- Cost Savings (28)

- Energy Savings (36)

- Evaporative Cooling (12)

- Green Ventilation (26)

- Heating (16)

- Hybrid Ventilation (7)

- Industrial Ventilation (107)

- Installation (32)

- Lunch & Learn (21)

- Maintenance (22)

- Manufacturing (14)

- Moffitt (38)

- Natural Cooling (16)

- Natural Daylighting (8)

- Natural Smoke Relief (9)

- Natural Solutions (48)

- Natural Ventilation (98)

- Natural Ventilator Maintenance (4)

- Powered Ventilation (44)

- Pressure Gravity System® (10)

- Product Comparison (13)

- Safety (22)

- Science (33)

- Testimonial (11)

- Wall Louvers (13)