Switching to Natural Ventilation

Have you considered switching to natural ventilation. For decades powered ventilation has been the standard in industry settings. While fans and blowers are the most effective way to ventilate some spaces, they are not the right fit in every situation.

Fortunately, there is natural ventilation. It is an industrial ventilation system design that uses no electricity, no blowers or fans, and no complicated ductwork to ventilate any industrial building completely, effectively, and efficiently.

How Natural Ventilation Works

A natural system design works on the principle that balmy air rises to create an updraft, much like an updraft created in a chimney. This is a fundamental pattern of natural airflow.

As the air rises, ventilators at the ceiling allow the stifling air to escape to the outside. When the heated air leaves the ventilator, it automatically draws in cooler and cleaner air from the ground level. This natural cycling of the cooler air replacing the warmer air works just as effectively as if it was accomplished using a powered blower, but a natural system uses no energy to do this. This is a very sustainable and “green” technology, and there is no noise pollution from blowing motors or fans. Better still, because there are no electrical motors, there are no parts to maintain or repair either.

A Design for Any Need

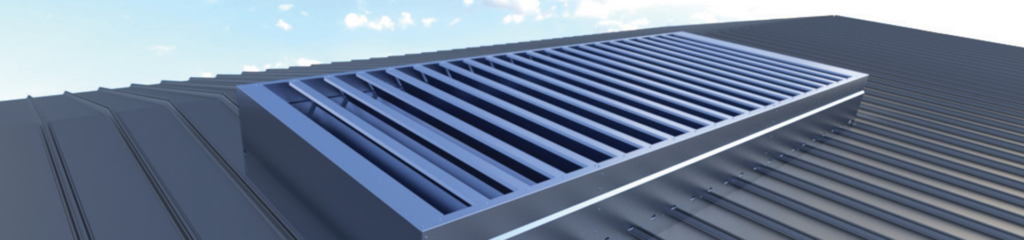

Moffitt is the world leader in natural ventilation system design. They feature several different types of ventilation fan that will work on any building structure. The MoffittVent Natural Ventilator is, in some ways, the simplest natural ventilator available. This special rooftop opening allows warm air to escape while protecting your building from the weather. Additionally, wall louvers down below pull in cool air to replace it.

Consider a low-profile natural ventilator for industries that produce high heat as a byproduct of production. This low-profile design, with baffles and aluminum louvers, give superior performance in all weather conditions. For smaller buildings, the turbine vent is a powerful solution. It removes hot stale air.

Cost Savings

With energy prices on the rise, mechanical ventilation has become a huge part for any industrial or commercial energy budget. It can take a lot of electrical power to run an industrial ventilation fan. Couple the operating costs with the added maintenance required to keep it running smoothly, plus the cost of repairs when the system breaks, and you’ll be looking at an overall expenditure that is twice the initial cost. That is not something that happens with a natural ventilation solution.

Contact Moffitt about Switching to Natural Ventilation

In conclusion, all Moffitt ventilation products are eco-friendly, they have no operating costs and require less maintenance. Every industrial application is different, but our team will custom-build a system for your specific building. We choose the right options and features to match your ventilation requirements. This includes special materials, coatings, and special configurations.

A Moffitt ventilation system design uses gravity ventilation to remove stale air effectively and efficiently from your building. These systems use no energy, have far less maintenance and incur no replacement costs. Unlike expensive burned-out motors or broken fans, they will save you money. Contact Moffitt if you are thinking about switching to natural ventilation in your factory.